IDEA

Having us on your side from the very first idea will facilitate the development of your product and project.

We offer a full range of services, supporting you from the first sketch to the dock to stock shipment of your final, sterile product.

Having us on your side from the very first idea will facilitate the development of your product and project.

In order to optimize the process and save time and cost, our R&D team provides you with the following services:

We specialize in prototyping, which allows to visualize the design and test the functionality of your device front-end. We offer:

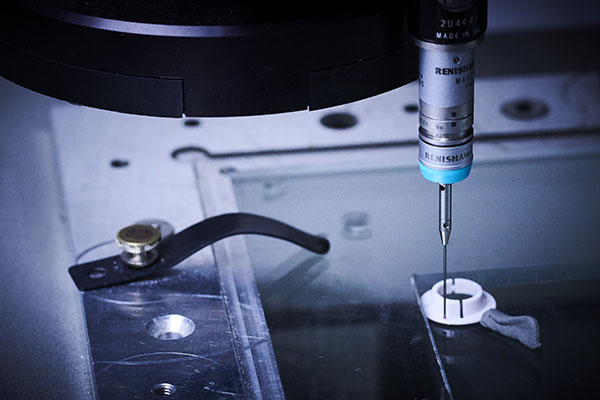

Every medical device must go through a series of validations. An experienced partner is needed prior to manufacturing to assure a short time-to-market. Our quality department assists you through the entire validation process of your device, support you through the FDA/CE-Documentation and Registration of your product.

Manufacturing is the core of our “Full-Service-Provider” philosophy. Thanks to our long-term experience in medical devices and state of the art manufacturing equipment, you will benefit from a short time-to-market and efficient scaling of production. A selection of our services provided to you:

Assembly is a crucial step in ensuring the reliability and cost-effectiveness of a medical device. In addition to manufacturing, the assembly process must be assessed front-end in the development of your device. Our industrialization teams will find the best balance between the different options.

Depending on your requirements, we provide validated processes for grey- and clean-room packaging, including:

We support your efforts in terms of distribution from consignment inventory through dock-to-stock shipments to VMI.